High production, high efficiency, practical, and preferred

INTEGRATED DESIGN

High production broad width carding machine can increase 40% of the effective yield.The carding, chute feeder, autoleveller integrated design, convenient, practical, good looking.

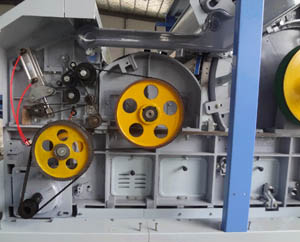

CYLINDER AND LICKER-IN ROLLER

Cylinder, licker-in adopt wide flat belt, transmission stable, reliable and durable.

DOFFER AND TRI-ROLLER

Doffer, tri-roller adopts frequency control, driven by synchronous toothed belt, so as to stepless speed regulation with flexibilityCROSS APRON FOR SLIVER GUIDING

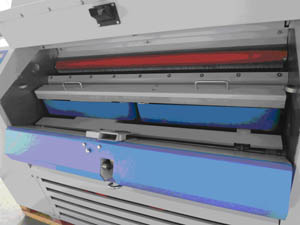

New type cross apron for sliver guiding, good effect for impurity removing, free maintenance, easy operation.

MULTI-POINT CONTINUOUS SUCTION

Multi-point continuous suction on card, clarity, good dust suction effect, pressure continuous detection.

ELECTRICAL CONTROL AND AUTOLEVELLING

Electric control system adopts imported PLC, touch screen and inverter, easy operation, the lifting speed or reduction speed is stable, and running stable and reliable; feeding system adopts advanced AFT032C autoleveller, fast reaction speed, high control accuracy, so inner and outer unevenness can be further improved.

MAIN TECHNICAL PARAMETER AND SPECIFICATIONS

|

No. |

ITEM |

SPECIFICATIONS |

|

1 |

Application |

The machine is used for processing cotton and chemical fibres or blends in length 22-76mm |

|

2 |

Sliver count(g/m) |

3.5~9.5 |

|

3 |

Sliver delivery speed(m/min) |

220£¨max£© |

|

4 |

Feed roller diameter (mm) |

¦Õ100 |

|

5 |

Feed roller pressure weight(N/cm) |

24.4¡«37 |

|

6 |

Mote knife adjustment |

Blade higher or lower the frame plane 6mm, the knife and frame plane with an angle of 85¦Ï¡«110¦Ï |

|

7 |

Licker-in diameter(mm) |

¦Õ250 |

|

8 |

Licker-in speed(r/min)

|

736¡¢803¡¢967

674¡¢736¡¢886 |

|

9 |

Cylinder diameter (mm) |

1288 |

|

10 |

Cylinder speed(r/min) |

326¡¢356¡¢380¡¢428 |

|

11 |

Flats working width(mm)

No. of revolving flats/total

Flats speed(mm/min) |

22

30/82

79¡«316 |

|

12 |

Doffer diameter(mm)

Doffer speed£¨r/min£© |

¦Õ706

24¡«63 |

|

13 |

Doffer silk head speed£¨r/min£© |

6¡«9 |

|

14 |

Cotton stripping |

Tri-roller striping and double apron guiding |

|

15 |

Attached carding segments |

Front stationary 4

Rear stationary 6

Carding segment under licker-in |

|

16 |

Total draft |

32~222 |

|

17 |

Delivery speed£¨m/min£© |

100~200 |

|

18 |

Can size£¨mm£© |

¦Õ600¡Á1100£¬¦Õ600¡Á1200

¦Õ1000¡Á1100 |

|

19 |

Total installed power(kw) |

About 8.9 |

|

20 |

Continucious suction(m3/h) |

3500 |

|

21 |

Continucious suction air pressure(Pa) |

-920 |

|

22 |

production(kg/h) |

Max 150 |

|

23 |

Sliver count£¨ktex£© |

3.5¡«6.5 |

|

24 |

Safety cover form |

Total-enclosed structure |

|

25 |

Space requirement (LxW)(mm) |

3442X2200 |

|

26 |

Approx net weight(kg) |

About 6000 |

|